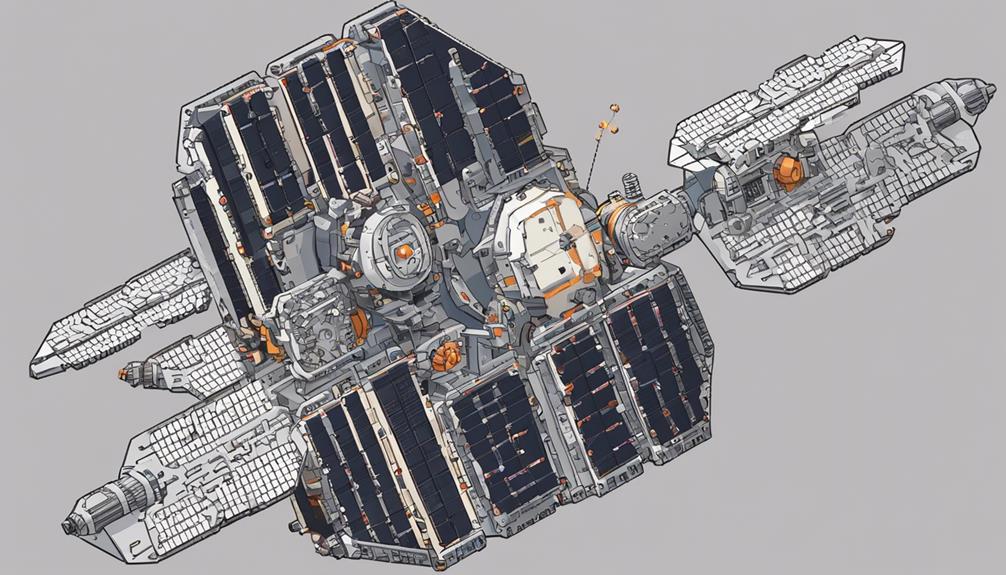

The integration of 3D printing technology in satellite manufacturing has revolutionized the industry, offering a myriad of benefits that were previously unattainable through traditional manufacturing methods. By leveraging the capabilities of additive manufacturing, satellite engineers can now produce intricate, lightweight components tailored to the specific needs of each mission. This precise and customizable approach not only enhances satellite performance but also opens up possibilities for increased cost efficiency and innovation. As the demand for advanced satellite systems continues to grow, exploring the intersection of 3D printing and satellite manufacturing holds promise for the future of space exploration and communication.

Key Takeaways

- Lightweight and robust structures enhance satellite performance.

- Customizable designs tailored to specific mission requirements.

- Cost-efficient production with optimized material utilization.

- Increased payload capacity and fuel efficiency revolutionize satellite manufacturing.

Benefits of 3D Printing in Satellite Manufacturing

The utilization of 3D printing technology in satellite manufacturing presents significant advantages, including the creation of robust and lightweight structures capable of withstanding the harsh conditions of lower earth orbit. By employing 3D printing techniques, satellite manufacturers can produce components that are not only strong but also lightweight, enabling increased payload capacity and enhanced overall performance of the satellite systems in space. This weight reduction is crucial in the space industry, where every gram matters in determining mission success.

Moreover, the customizable nature of 3D printing allows for intricate designs tailored to specific mission requirements, offering flexibility in creating mounting opportunities for various satellite components. This level of customization is particularly beneficial in the space sector, where each mission may have unique specifications that demand precise engineering solutions.

Furthermore, 3D printing enables the production of optimized components such as thermal management and radio-frequency parts for satellites. These intricate components can be challenging to manufacture using traditional methods but are efficiently achievable through 3D printing, showcasing the technology's versatility and precision in creating complex structures for space applications.

Components Utilized in 3D Printing

Utilizing advanced additive manufacturing techniques, satellite manufacturers employ a diverse range of components in 3D printing processes to enhance satellite functionality and performance. In satellite manufacturing, complex components such as thermal management systems and radio-frequency parts are crucial for ensuring optimal satellite operations. The semiconductor industry has played a significant role in enabling nanometer accuracy in chip production for satellite components, contributing to the high precision required in satellite technology.

However, the lack of standardization in satellite manufacturing poses challenges for scaling up the benefits of 3D printing. Efforts are underway to streamline manufacturing processes and integrate 3D printing more effectively into satellite production. This includes addressing issues faced by small satellite manufacturers, such as the need for human intervention and cost considerations when implementing 3D printing technology.

As satellite technology continues to advance, the incorporation of 3D printing in manufacturing processes offers a promising avenue for creating intricate and customized components. By leveraging the capabilities of 3D printing, satellite manufacturers can enhance the performance and efficiency of satellites, meeting the demands of the ever-evolving aerospace industry.

Structural Applications of 3D Printing

In the realm of satellite manufacturing, the structural applications of 3D printing offer advantages in designing complex geometries and optimizing lightweight materials. This technology allows for intricate designs that were previously unattainable using traditional manufacturing methods, enhancing the overall performance of satellite components. Moreover, the optimization of lightweight materials through 3D printing contributes to increased efficiency and cost-effectiveness in satellite production processes.

Designing Complex Geometries

Enabling the fabrication of intricate and optimized structural components, 3D printing technology revolutionizes the design of complex geometries in satellite manufacturing. By utilizing 3D printing, engineers can produce lightweight parts with intricate and unique shapes that are tailored to specific mission requirements. The ability to design complex geometries through additive manufacturing enhances the overall performance and functionality of satellite structures. Printed parts can be customized to reduce weight, increase efficiency, and improve the overall structural integrity of satellites. Traditional manufacturing methods are limited in their capability to replicate such geometrically complex components, making 3D printing a crucial technology in advancing satellite design and manufacturing processes.

Lightweight Material Optimization

The application of lightweight material optimization in satellite manufacturing through 3D printing technology is paramount for achieving enhanced structural efficiency and performance. 3D printing enables the production of strong and lightweight structures necessary for satellites operating in lower earth orbit. Weight reduction achieved through 3D printing not only increases payload capacity but also enhances the overall performance of satellite components. Customizable designs made possible by 3D printing offer mounting opportunities tailored to specific mission requirements. Components produced using 3D printing technology can withstand extreme conditions encountered in space environments, ensuring reliability in operation. This weight reduction in satellite components enhances fuel efficiency and operational capabilities, making 3D printing a crucial technology in satellite manufacturing.

| Benefits of 3D Printing in Satellite Manufacturing |

|---|

| Enhanced structural efficiency |

| Weight reduction for increased payload capacity |

| Ability to withstand extreme conditions |

Advantages for Satellite Industry

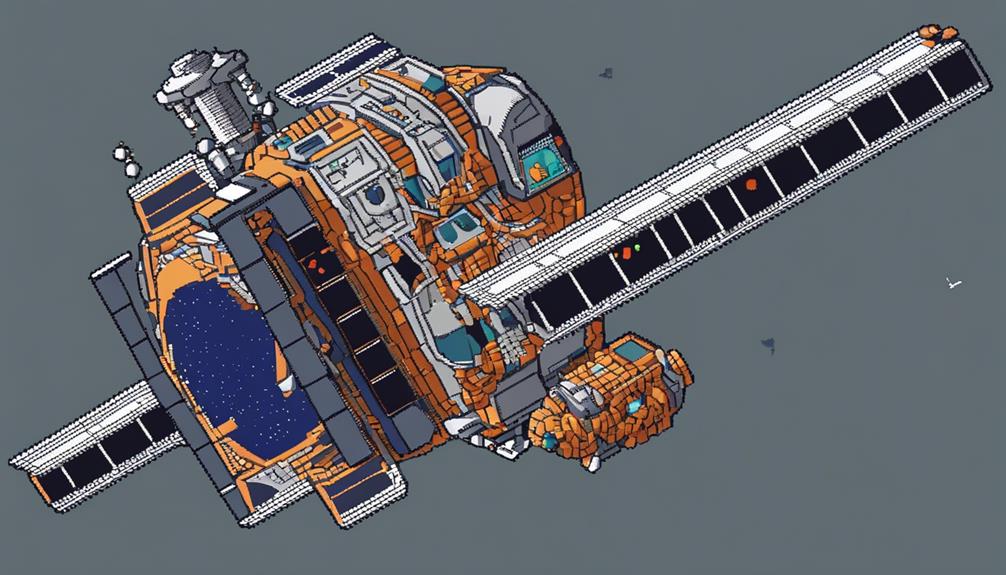

Facilitating unparalleled customization and adaptability, 3D printing in the satellite industry revolutionizes manufacturing processes to meet specific mission requirements efficiently. One significant advantage lies in the production of printed parts that are lighter in weight compared to traditionally manufactured components. This reduction in weight not only enhances fuel efficiency but also increases the satellite's payload capacity, allowing for more equipment or scientific instruments to be carried onboard.

Moreover, additive manufacturing in satellites leads to the creation of optimized components that contribute to improved overall performance. By 3D printing complex parts like thermal management systems and radio-frequency components, manufacturers can achieve designs that were previously unattainable through conventional methods. This capability to produce intricate and custom parts tailored to the satellite's needs is a game-changer in the industry.

Companies such as Thales Alenia Space have already embraced 3D printing technologies to manufacture satellite components like aluminum antenna supports successfully. This adoption highlights the practical application and benefits of additive manufacturing in the satellite sector, showcasing how printed parts can meet stringent requirements while offering enhanced performance characteristics. The advantages brought by 3D printing in satellite manufacturing underscore its pivotal role in advancing the capabilities and efficiency of satellite systems.

Cost-Efficiency and 3D Printing

The cost savings associated with 3D printing in satellite manufacturing stem from the ability to optimize material usage and reduce waste, leading to more efficient production processes. Understanding the various material options and their associated costs is crucial for determining the overall cost-effectiveness of utilizing 3D printing in satellite manufacturing. By strategically selecting materials and leveraging the capabilities of 3D printing technology, satellite manufacturers can achieve significant cost efficiencies while maintaining high-quality standards.

Cost Savings With 3D Printing

Emphasizing the paramount importance of cost efficiency in satellite manufacturing, the utilization of 3D printing technology has proven instrumental in driving substantial reductions in production expenses.

Key Points:

- New Additive Manufacturing: 3D printing introduces innovative production methods in the aerospace industry.

- Reduction in Production Costs: The aerospace sector benefits from lowered costs through 3D printing technologies.

- Significant Cost-Efficiency: Airbus Defence and Space achieved a 20% reduction in production costs by utilizing 3D printing, showcasing tangible benefits in cost savings.

These advancements highlight the crucial role of 3D printing in revolutionizing satellite manufacturing processes, allowing for more cost-effective and efficient production methods.

Material Options and Costs

In the realm of satellite manufacturing, the strategic selection of materials plays a pivotal role in determining both cost-efficiency and performance outcomes, particularly when considering the integration of 3D printing technologies. Metal 3D printing for satellite components can offer cost-effective solutions, especially when produced at scale, leading to significant reductions in production costs. Additive manufacturing enables material optimization and the creation of lightweight designs, contributing to overall cost-efficiency in satellite manufacturing. Advanced materials such as titanium and aluminum can be effectively utilized in 3D printing for satellite parts, striking a balance between cost and performance requirements. The versatility of 3D printing allows for the use of various materials, providing cost-effective options tailored to specific satellite needs. Cost considerations in material selection for 3D printing in satellites involve a careful balance of performance, durability, and affordability.

Enhancing Satellite Performance With 3D Printing

Utilizing additive manufacturing techniques such as 3D printing in satellite manufacturing significantly enhances overall performance by producing optimized, lighter, and stronger components. This advancement in technology has revolutionized the industry by allowing for the creation of intricate designs that were previously impossible to achieve using traditional manufacturing methods. The following points highlight how 3D printing elevates satellite performance:

- Improved Reliability and Fuel Efficiency: By reducing the weight of satellites through additive manufacturing, increased reliability and fuel efficiency are achieved. The lighter components enabled by 3D printing contribute to overall operational effectiveness and cost savings.

- Increased Payload Capacity: Lightweight 3D-printed components directly translate to increased payload capacity for satellites. This enhancement allows for more equipment or scientific instruments to be carried, amplifying the satellite's functionality and mission capabilities.

- Enhanced Rocket Performance: Industry leaders like SpaceX have harnessed the power of 3D printing by incorporating 3D-printed engine nozzles in their rockets. This implementation has led to significant improvements in overall rocket performance, demonstrating the impact of additive manufacturing on the production of printed rockets.

Incorporating 3D printing in satellite production not only enhances performance but also drives innovation, cost-efficiency, and sustainability within the satellite manufacturing sector.

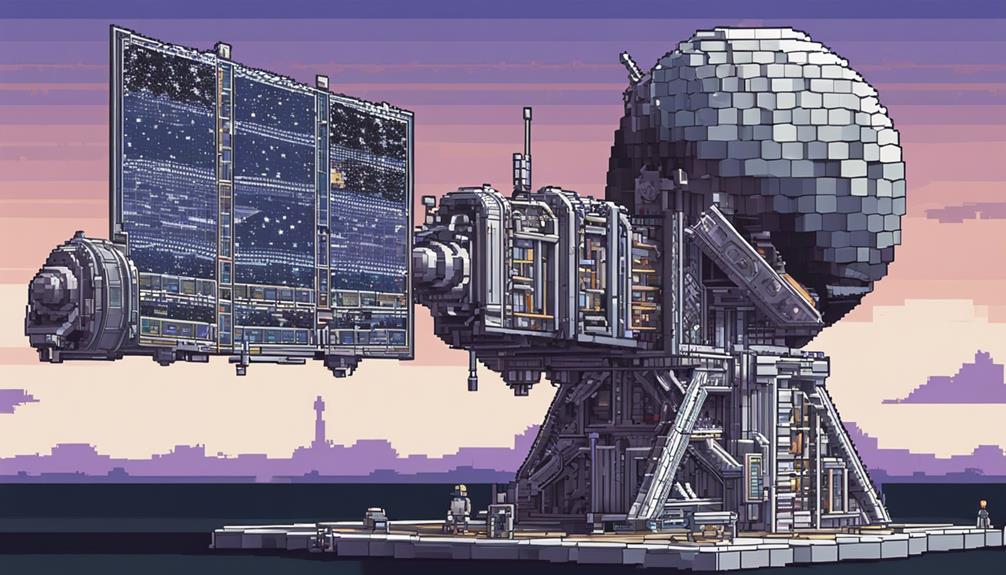

In-Orbit Maintenance With 3D Printing

Deploying cutting-edge additive manufacturing techniques, particularly 3D printing, for in-orbit maintenance revolutionizes the capabilities of astronauts aboard the International Space Station (ISS). This manufacturing technology allows astronauts to fabricate spare parts and tools on-demand, significantly enhancing their self-sufficiency during space missions. NASA's In-space manufacturing project plays a crucial role in evaluating and testing 3D printing systems in the unique zero-gravity environment of space, ensuring the feasibility and reliability of this innovative approach to in-orbit maintenance. By utilizing 3D printing in space, astronauts can address maintenance issues promptly by producing critical components without the need to wait for resupply missions from Earth. This capability not only streamlines in-orbit maintenance but also reduces the reliance on Earth for essential spare parts, contributing to the sustainability of long-duration space exploration missions.

| Benefits of In-Orbit Maintenance with 3D Printing | |||

|---|---|---|---|

| On-demand fabrication of spare parts | Customized tools creation for space missions | Enhanced self-sufficiency of astronauts | Reduction in dependence on Earth for resupply |

Micro and Nanosatellites in 3D Printing

Enhancing the capabilities of micro and nanosatellites, 3D printing technology offers a cost-effective and efficient solution for producing intricate and lightweight components tailored to the unique requirements of small satellite projects. This marks the first time a satellite, particularly a communications satellite, utilizes 3D printing to achieve its mission objectives.

Advantages of 3D Printing in Micro and Nanosatellites:

- Customization: Additive manufacturing enables the creation of highly customized components, essential for adapting to the specific needs of micro and nanosatellite missions.

- Rapid Prototyping: The ability to quickly prototype parts allows for faster design iterations, crucial for the development of small satellites where time is of the essence.

- Cost-Effectiveness: Reduced production costs associated with 3D printing make it an attractive option for small satellite projects with limited budgets, promoting innovation in the field of satellite technology.

The use of 3D printing technology in micro and nanosatellites not only addresses the challenges posed by the small size and weight constraints of these satellites but also paves the way for advancements in miniaturized satellite technology. By leveraging the benefits of additive manufacturing, small satellite developers can achieve greater flexibility, efficiency, and cost savings in their endeavors.

Practical Examples of 3D Printing in Satellites

The application of 3D printing technology in satellite manufacturing has demonstrated significant advancements through practical examples in the aerospace industry. Companies like Airbus Defence and Space have successfully reduced bracket weight by 300g and production costs by 20% by utilizing 3D printing techniques. This reduction in weight is crucial for satellites as it can lead to improved fuel efficiency and overall performance. Furthermore, Boeing has leveraged 3D printing to accelerate satellite production timelines, showcasing the technology's ability to streamline manufacturing processes.

Researchers at MIT have also made notable strides in the field by 3D printing plasma sensors for satellite sensors, demonstrating cost reductions and enhanced sensor capabilities. The ability to create fully 3D printed components has enabled customization, lightweight parts, and significant cost reductions in satellite production. This innovative approach not only enhances the performance of satellites but also contributes to overall cost-effectiveness in the aerospace industry. Additionally, 3D printing facilitates rapid prototyping and component customization, further reducing production times and allowing for more efficient manufacturing processes in satellite development. The practical examples of 3D printing in satellites highlight the technology's potential to revolutionize the industry and drive further innovation in space technology.

Future of 3D Printing in Satellite Industry

The future of 3D printing in the satellite industry holds immense potential in terms of efficiency, material innovation, and cost-effective production. By leveraging advanced 3D printing technologies, satellite manufacturers can streamline their production processes, enabling quicker turnaround times and enhanced customization options. Moreover, the ability to experiment with novel materials and design concepts through additive manufacturing opens up new frontiers for satellite development, paving the way for cutting-edge advancements in the field.

3D Printing Efficiency

Advancements in 3D printing technology are poised to significantly optimize manufacturing processes within the satellite industry, ushering in a new era of efficiency and innovation.

Key Points:

- Additive manufacturing techniques will streamline satellite production, reducing complexities in assembly processes.

- Innovative design capabilities enabled by 3D printing will enhance satellite performance, leading to higher efficiency and reliability.

- Cost-effective and time-efficient manufacturing through 3D printing methods will drive the future of satellite industry, allowing for quicker deployment and increased customization options.

These developments signify a fundamental shift towards improved efficiency and performance in satellite manufacturing, laying the groundwork for a more agile and advanced industry landscape.

Material Innovation

In the realm of satellite manufacturing, the evolution of 3D printing materials presents a trajectory towards unparalleled innovation and efficiency. Metal 3D printing techniques have enabled the creation of intricate and robust satellite components using advanced materials such as titanium and aluminum alloys. The ability to utilize carbon fiber-reinforced polymers in 3D printing for satellite applications has allowed for the production of lightweight yet high-strength parts. Additive manufacturing processes play a crucial role in enhancing material properties and overall performance in satellite manufacturing. This continuous exploration and implementation of novel materials showcase the significant advancements in additive manufacturing technologies within the satellite industry.

| Material | Application | Benefits |

|---|---|---|

| Titanium Alloys | Structural Components | High Strength, Lightweight |

| Aluminum Alloys | Satellite Frames | Durable, Corrosion-Resistant |

| Carbon Fiber-Reinforced Polymers | Antenna Components | Lightweight, High Mechanical Strength |

| Advanced Composites | Solar Panels | Enhanced Thermal Stability, Efficiency |

Cost-Effective Production

Pioneering cost-effective methodologies through additive manufacturing heralds a transformative era in satellite industry production. 3D printing in the satellite industry offers significant cost savings by reducing material waste and optimizing part designs. Key aspects include:

- Efficient Production: 3D printing enables the creation of complex satellite components at a lower cost than traditional manufacturing methods.

- Customization and Adaptability: Cost-effective customization is achievable through 3D printing, meeting specific mission requirements without costly tooling changes.

- Competitive Advantage: Space companies benefit from reduced production expenses, enhancing competitiveness in the industry. 3D printing is a valuable solution for optimizing costs and driving efficiency in satellite manufacturing.

Frequently Asked Questions

How 3D Printing Is Used in Manufacturing?

Material properties, design flexibility, and cost savings are key advantages of 3D printing in manufacturing. This technology allows for the creation of intricate designs with varying material properties, enhancing performance. Design flexibility permits rapid prototyping and customization. Cost savings are achieved through reduced material waste and streamlined production processes. Overall, 3D printing revolutionizes manufacturing by offering innovative solutions that traditional methods cannot match.

What Is 4D Printing in Additive Manufacturing?

4D printing in additive manufacturing is a cutting-edge technology that enables objects to self-transform post-printing in response to external stimuli. Innovations in material science have paved the way for materials that can adapt to temperature, light, or humidity triggers. This advancement offers exciting future applications like self-assembling structures and adaptive medical devices. Challenges lie in material innovation for sustainability, ensuring design flexibility, and enhancing time efficiency in the manufacturing process.

How Can You Use 3D Printing to Disrupt an Industry?

Utilizing 3D printing can disrupt an industry through supply chain optimization, cost reduction, and design flexibility. By leveraging additive manufacturing processes, companies can streamline production, minimize inventory, and accelerate time-to-market. This technology enables intricate designs, reduces material wastage, and offers customization at a lower cost. Such benefits revolutionize traditional manufacturing methods, leading to increased efficiency, innovation, and competitiveness within the industry.

Can You 3D Print a Satellite?

Satellite customization through 3D printing offers unparalleled efficiency in space missions. This innovative technology allows for intricate designs and tailored components, enhancing satellite performance. The ability to produce lightweight, complex structures with additive manufacturing techniques opens doors for future applications in satellite manufacturing. As advancements continue, entirely 3D printed satellites might soon become a reality, revolutionizing the industry with cost-effective solutions and improved functionality.