Industrial IoT (IIoT) hardware solutions are at the forefront of revolutionizing the industrial landscape, enabling connectivity, data collection, and analysis in ways never seen before. These rugged and reliable devices form the backbone of Industry 4.0 initiatives, facilitating real-time monitoring, automation, and optimization of industrial processes.

With durability and precision as key attributes, IIoT hardware solutions offer enhanced efficiency, productivity, and cost savings. But what specific features and capabilities do these hardware solutions possess? How are they designed to withstand the harsh conditions of industrial environments?

This discussion aims to explore the intricacies of IIoT hardware solutions, uncovering the technologies and innovations that power the industrial revolution.

Key Takeaways

- Industrial IoT hardware is designed with enhanced durability features such as ruggedized enclosures and robust components to withstand harsh industrial environments.

- Reliability and scalability are crucial factors for IIoT hardware, with features like redundancy, failover mechanisms, regular updates, and scalability to support advanced analytics and machine learning.

- IIoT hardware solutions cater to specific applications such as asset tracking, inventory management, and machine monitoring, enabling seamless data transfer and data-driven decision-making.

- Durability and precision are important aspects of IIoT hardware, ensuring reliable and accurate data collection, transmission, and control in challenging industrial conditions.

Rugged and Reliable IIoT Hardware

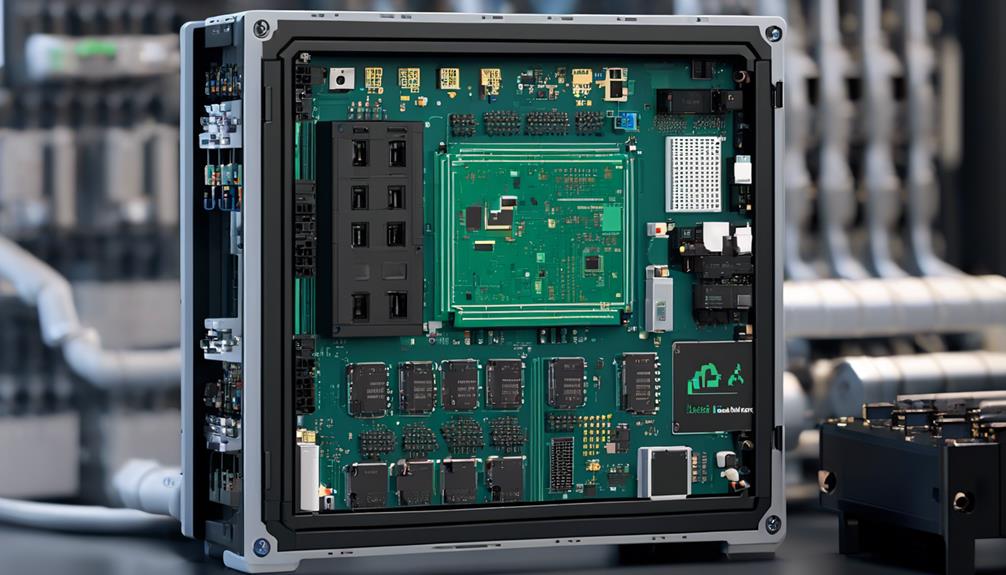

Rugged and reliable IIoT hardware is specially designed to withstand the harsh conditions of industrial environments, ensuring continuous operation and minimal downtime. These specialized hardware solutions are built to endure extreme temperatures, moisture, vibrations, and other challenging factors commonly found in industrial settings. Equipped with robust enclosures and protective measures, rugged and reliable IIoT devices offer high durability and longevity.

One of the key advantages of using rugged and reliable IIoT hardware is its ability to provide real-time visibility into industrial equipment and processes. These devices enable seamless data collection from various sensors and machines, allowing for comprehensive data management and analysis. With real-time visibility, operators and managers can gain valuable insights into machine performance, identify potential issues, and make informed decisions to optimize productivity and efficiency.

Moreover, rugged and reliable IIoT hardware plays a crucial role in machine monitoring and predictive maintenance. By continuously monitoring equipment, these devices can detect anomalies, predict failures, and trigger alerts, enabling proactive maintenance actions. This predictive maintenance approach helps prevent unexpected breakdowns, reduce unplanned downtime, and ultimately extend the lifespan of industrial assets.

Precision-driven IIoT Solutions

Precision-driven IIoT solutions offer a range of benefits for industrial operations.

By leveraging real-time data, these solutions enable data-driven efficiency optimization, allowing businesses to make informed decisions and enhance operational performance.

Additionally, precision-driven IIoT solutions provide real-time performance monitoring and predictive maintenance capabilities. This enables proactive maintenance to prevent equipment failures and optimize productivity.

Data-Driven Efficiency Optimization

Data-driven efficiency optimization is a key focus of precision-driven IIoT solutions. These solutions leverage AI-based recommendations and real-time machine data analysis to improve overall equipment effectiveness and maintenance scheduling. By harnessing the power of data, manufacturers can make more informed decisions and optimize their operations for maximum efficiency.

Here are three key benefits of data-driven efficiency optimization in the industrial IoT:

- Increased machine availability: Real-time insights into machine performance and health enable proactive maintenance, reducing unplanned downtime and maximizing machine availability.

- Improved decision-making: Data-driven decision-making allows manufacturers to identify bottlenecks, optimize processes, and allocate resources effectively, leading to improved overall efficiency.

- Enhanced operational efficiency: By analyzing data in real-time, manufacturers can identify inefficiencies and implement targeted improvements to optimize production processes, reduce waste, and increase productivity.

With data-driven efficiency optimization, the industrial IoT is revolutionizing the manufacturing industry, enabling manufacturers to achieve new levels of productivity and profitability.

Real-Time Performance Monitoring

Real-Time Performance Monitoring is a crucial component of precision-driven IIoT solutions, enabling continuous tracking and analysis of machine data in real-time. It provides industrial operations with the ability to monitor and manage equipment efficiency, machine health, and asset optimization.

By collecting and analyzing real-time data, performance management becomes proactive rather than reactive. This solution allows for the identification of abnormal patterns and predicts potential equipment failures, enabling timely maintenance interventions. Real-Time Performance Monitoring also offers automated notifications about equipment defects, facilitating proactive maintenance and reducing downtime.

With visualized floor plans and location maps, customizable role-based reports on machine availability, condition, and performance can be generated. By leveraging insights gained from real-time monitoring and analysis, industrial processes can be optimized, leading to improved operational efficiency and productivity.

Predictive Maintenance Solutions

Predictive Maintenance Solutions leverage AI-based recommendations to optimize equipment maintenance and minimize potential breakdowns. These solutions offer real-time equipment monitoring and provide alerts about upcoming regular maintenance, potential breakdowns, and expected time to failure.

By analyzing machine and equipment data, they can predict potential breakdowns and optimize maintenance scheduling. Predictive Maintenance Solutions empower proactive diagnosing and fixing of equipment defects, leading to significant cost savings and operational efficiency improvements.

They also help in planning equipment modernization, replacement, or disposal based on equipment data analysis. Implementing these solutions in IIoT projects can reduce unplanned downtime, increase productivity, and improve overall equipment effectiveness.

Durable Hardware for Industrial Applications

Durable hardware designed for industrial applications must withstand extreme environmental conditions and operate continuously. Industrial IoT (IIoT) hardware solutions play a vital role in connecting machines and enabling data-driven decision-making on the production line and shop floor. These hardware components need to have a robust design to ensure reliability and longevity in demanding industrial settings.

Industrial hardware must be resistant to temperature variations, shock, vibration, and dust. It should be able to tolerate high and low temperatures to function optimally in different environments. Moreover, the hardware should be built to withstand physical stresses such as shocks and vibrations that are common on the shop floor. Dust and other particles can also cause damage to the hardware, so it must be well-protected to ensure uninterrupted operation.

In addition to durability, industrial hardware must support continuous data generation and sharing. Components like sensors, controllers, and edge devices need to be capable of collecting and transmitting data in real-time. This data is crucial for monitoring and optimizing production processes, enabling predictive maintenance, and improving overall operational efficiency.

Furthermore, industrial hardware should facilitate seamless integration with IIoT software and analytics platforms. The hardware should be compatible with the IIoT platform to enable real-time data processing and actionable insights. A secure IIoT ecosystem is essential to protect sensitive data and maintain the integrity of industrial operations.

Industrial IoT Hardware for Enhanced Durability

Industrial IoT hardware designed for harsh industrial environments is engineered to withstand extreme conditions and ensure uninterrupted and reliable operation of critical processes and equipment. Here are three key features of industrial IoT hardware for enhanced durability:

- Ruggedized Enclosures: Industrial IoT hardware solutions incorporate ruggedized enclosures that provide protection against dust, moisture, and physical damage. These enclosures are designed to withstand extreme temperatures, vibrations, and other challenging environmental conditions. By safeguarding the internal components, ruggedized enclosures prevent potential problems and ensure the longevity of the hardware.

- Robust Components: Industrial IoT hardware for enhanced durability utilizes robust components that can withstand the rigors of industrial environments. These components are carefully chosen to ensure reliability and minimize maintenance requirements. For example, industrial-grade sensors are used to collect and transmit accurate sensor data, even in demanding conditions. By employing durable components, industrial IoT hardware can operate consistently and provide accurate data for efficient decision-making.

- Data Storage and Analysis: Durability in industrial IoT hardware also extends to data storage and analysis capabilities. With the ability to handle large volumes of data, industrial IoT hardware solutions enable efficient storage and analysis of sensor data. This allows industrial processes to be monitored in real-time, identifying potential issues and optimizing production efficiency. By leveraging the power of data analytics, industrial IoT hardware helps improve efficiency, minimize downtime, and enhance overall productivity in industrial settings.

Industrial IoT hardware designed for enhanced durability plays a crucial role in maintaining the efficiency and reliability of critical industrial processes. By withstanding extreme conditions, preventing potential problems, and enabling efficient data storage and analysis, these hardware solutions ensure uninterrupted operation and contribute to the success of industrial organizations.

High-Quality IIoT Hardware Solutions

High-quality IIoT hardware solutions are essential for ensuring reliability and scalability in industrial environments. These solutions provide the necessary foundation for real-time tracking, monitoring, and optimization of equipment and assets in smart factories.

Reliability in IIoT Hardware

Reliability is a critical aspect of IIoT hardware, ensuring consistent performance in demanding industrial environments. To evoke an emotional response in the audience, here are three key factors contributing to the reliability of IIoT hardware:

- Robust Design: High-quality IIoT solutions are designed to withstand harsh conditions and provide uninterrupted operation. This instills confidence in machine equipment and maximizes asset effectiveness.

- Redundancy and Failover Mechanisms: IIoT hardware with redundancy and failover mechanisms minimizes downtime and ensures continuous operations. This reduces the risk of disruptions and improves overall equipment reliability.

- Long-term Support and Maintenance: Timely support, maintenance, and firmware updates are crucial for the reliability of IIoT hardware. Regular updates address security vulnerabilities, enhance performance, and prolong the lifespan of the equipment.

Incorporating these reliability measures in IIoT solutions helps minimize data silos, optimize operations, and maximize asset performance, ultimately leading to improved productivity in industrial IoT environments.

Scalability of IIoT Solutions

To ensure seamless integration with a growing number of devices and sensors in industrial environments, IIoT hardware solutions must possess the capability of scalability.

Scalability in IIoT solutions refers to the ability to easily expand the system to accommodate additional machinery, assets, and production lines as the business grows. This scalability ensures that the hardware can adapt to increasing data volumes and processing requirements without compromising performance.

By being scalable, IIoT hardware solutions can support the implementation of advanced analytics, machine learning, and AI technologies, enabling more comprehensive insights and predictive capabilities.

Moreover, as industrial operations evolve, scalable IIoT hardware solutions can be upgraded or augmented with new features and functionalities to meet changing business needs and technological advancements. This flexibility is crucial in an industrial setting where the Internet of Things (IIoT) plays a significant role in optimizing production, machine maintenance, and the overall efficiency of the supply chain.

Hardware Solutions for Industrial IoT Applications

Industrial IoT applications rely on hardware solutions to enable real-time monitoring and analysis of machine data for predictive maintenance and improved performance. These hardware solutions play a crucial role in collecting and processing data from various machines and devices in industrial settings.

Here are three key hardware solutions for industrial IoT applications:

- Asset tracking solutions: These solutions utilize interactive maps and geofencing to monitor asset location, movement, and maintenance alerts. By providing real-time visibility into the whereabouts of assets, businesses can optimize their operations, prevent loss or theft, and streamline maintenance processes.

- Inventory management hardware solutions: These solutions offer automated replenishment triggers, lot and serial number tracking, and optimal safety stock calculation. With the ability to track inventory levels in real-time, businesses can reduce stockouts, minimize excess inventory, and improve overall supply chain efficiency.

- Machine monitoring hardware: This hardware provides customizable role-based reports on machine availability, condition, and performance, along with predictive maintenance capabilities. By continuously monitoring machines, businesses can identify potential issues before they result in costly downtime or failures. Predictive maintenance helps optimize maintenance schedules, reduce costs, and prolong the lifespan of equipment.

These hardware solutions enable seamless data transfer between IoT-enabled devices and the cloud computing infrastructure. They also facilitate data visualization, allowing businesses to gain valuable insights and make data-driven decisions. With the right hardware solutions in place, industrial IoT applications can unlock the full potential of the Industrial Internet of Things, leading to increased productivity, cost savings, and improved operational efficiency.

Robust and Precise IIoT Hardware

With the demand for continuous and reliable operation in demanding industrial environments, robust and precise IIoT hardware plays a crucial role in ensuring accurate data collection and monitoring capabilities for critical industrial processes.

IIoT hardware solutions are designed to withstand harsh conditions, including temperature variations, humidity, and vibration. These hardware solutions offer precise measurement and monitoring capabilities for critical industrial processes, providing accurate and high-quality data collection from connected sensors and equipment.

In the era of digital transformation, the Internet of Things (IoT) has revolutionized the industrial sector. IIoT solutions have enabled organizations to reduce operational costs, enhance overall efficiency, and improve decision-making processes.

Robust and precise IIoT hardware is the foundation of these solutions, enabling seamless connectivity and data exchange between physical objects and the digital world.

The data collected by IIoT hardware helps organizations gain real-time insights into their operations and enables them to perform root cause analysis for continuous improvement. This data can be used to implement lean manufacturing practices, optimize production processes, and minimize downtime.

Furthermore, robust and precise IIoT hardware ensures the reliability and accuracy of the data collected, which is crucial for critical industrial processes. By providing accurate and high-quality data, IIoT hardware supports organizations in making informed decisions, increasing productivity, and ensuring the safety of their operations.

Durability and Precision in IIoT Hardware

Ensuring reliable and accurate data collection and transmission in harsh industrial environments, durability and precision are paramount in IIoT hardware. Industrial-grade hardware components are designed to withstand extreme temperatures, humidity, and vibrations, ensuring continuous operation in challenging conditions. High precision sensors and actuators provide accurate measurements and control, essential for maintaining quality and efficiency in industrial processes. Ruggedized enclosures and robust construction of IIoT hardware ensure longevity and minimal maintenance requirements in industrial settings. The use of high-quality materials and components in IIoT hardware guarantees reliability and accuracy, contributing to improved operational performance and reduced downtime.

To evoke an emotional response in the audience, consider the following:

- Unprecedented Visibility: IIoT hardware with durability and precision provides unprecedented visibility into industrial processes. This empowers organizations to detect problems and prevent potential issues before they escalate, ensuring safe and efficient operations.

- Improved Efficiency: With durable and precise IIoT hardware, organizations can diagnose problems and identify bottlenecks in real-time. This allows for timely intervention and optimization of processes, leading to improved efficiency and overall productivity.

- Enhanced Safety: IIoT hardware with durability and precision enables organizations to ensure safe work environments by accurately monitoring critical parameters. This allows for early detection of anomalies and immediate action to prevent accidents or equipment failures.

Industrial-grade Hardware for IIoT Applications

To enable seamless integration into existing industrial setups, robust and durable industrial-grade hardware is essential for IIoT applications. Industrial IoT (IIoT) hardware solutions need to be able to withstand the harsh environments found in industrial settings. These hardware solutions should support connectivity with a wide range of industrial sensors and devices, ensuring that they can easily integrate into existing setups and gather relevant data.

One of the key advantages of IIoT applications is the ability to collect and analyze real-time data to improve efficiency in manufacturing and factory operations. Industrial-grade hardware plays a crucial role in this process by providing the necessary infrastructure to capture and process data from various machines and devices. This data can then be used for machine utilization analysis, predictive maintenance, and optimizing production processes.

Furthermore, industrial-grade hardware should also offer advanced security features. With the increasing threat of cyber attacks, it is imperative that IIoT hardware solutions have robust security mechanisms in place to protect against unauthorized access and ensure the integrity of industrial data.

Scalability and adaptability are also important considerations when choosing industrial-grade hardware for IIoT applications. As industrial environments evolve and new technologies emerge, the hardware should be able to accommodate new requirements and seamlessly integrate with other systems.

Frequently Asked Questions

What Is an Industrial Iot Device?

An industrial IoT device is a sophisticated tool used in high-stakes industries to collect and exchange real-time sensor data. These devices play a crucial role in various industrial IoT applications, such as machine monitoring, predictive maintenance, and asset tracking. They provide numerous benefits, including improved efficiency, optimized production processes, and reduced operational costs.

Sensors are integral components of industrial IoT devices, enabling accurate data capture. However, security challenges exist in industrial IoT, necessitating the integration of cloud computing and the use of wireless connectivity options.

Real-time data analytics and predictive maintenance enhance device management and monitoring.

What Are Iot Solutions?

IoT solutions, also known as Internet of Things solutions, refer to the implementation of connected devices and systems to collect, exchange, and analyze data for various industries. These solutions offer numerous benefits such as improved efficiency, cost savings, and enhanced decision-making.

In healthcare, IoT solutions enable remote patient monitoring and predictive maintenance of medical equipment. In agriculture, they optimize crop management and irrigation. However, challenges like data privacy and security must be addressed.

Future trends include IoT solutions for smart cities, energy management, transportation, and logistics.

What Three Areas Need to Be Focused on With IIoT Implementations?

To implement IIoT successfully, three key areas need to be focused on:

- Data analytics: Data analytics helps in extracting valuable insights from the vast amount of data generated by IIoT devices.

- Real-time monitoring: Real-time monitoring ensures that equipment and processes are continuously monitored for optimal performance.

- Predictive maintenance: Predictive maintenance enables proactive identification and resolution of issues, reducing downtime.

These areas must be addressed while considering:

- Connectivity options

- Security measures

- Scalability challenges

- Edge computing

- Interoperability issues

- Cost-effective solutions.

How Does the IIoT Improve Maintenance and Repair of Industrial Equipment?

Predictive maintenance, remote monitoring, and real-time diagnostics are some of the ways in which IIoT improves maintenance and repair of industrial equipment.

By analyzing equipment condition and identifying potential breakdowns before they occur, IIoT enables proactive maintenance, minimizing downtime and improving equipment efficiency. This leads to cost savings and enhanced safety measures.

Additionally, condition-based maintenance and improved equipment lifespan are achieved through continuous monitoring and data analysis, ensuring optimal performance and reducing the risk of equipment failure.