Amidst the vast expanse of space, the realm of satellite on-orbit servicing and refueling emerges as a critical domain, revolutionizing the traditional paradigms of satellite operations. The intricacies of this field delve into the realms of advanced robotic systems, cutting-edge refueling techniques, and the standardization of spacecraft interfaces. As the industry witnesses a surge in capabilities and a shift towards sustainable practices, the implications for future space missions are profound. This evolving landscape presents a tantalizing glimpse into the possibilities that lie ahead, beckoning exploration into the uncharted territories of space technology and operational excellence.

Key Takeaways

- Evolution of satellite servicing includes autonomous missions and part recycling.

- Advancements in refueling techniques enable efficient on-orbit satellite refueling.

- Key technologies like AFTI and MAP enhance on-orbit operations and servicing.

- Satellite servicing ensures mission sustainability, resilience, and longevity for future space endeavors.

Evolution of Satellite Servicing

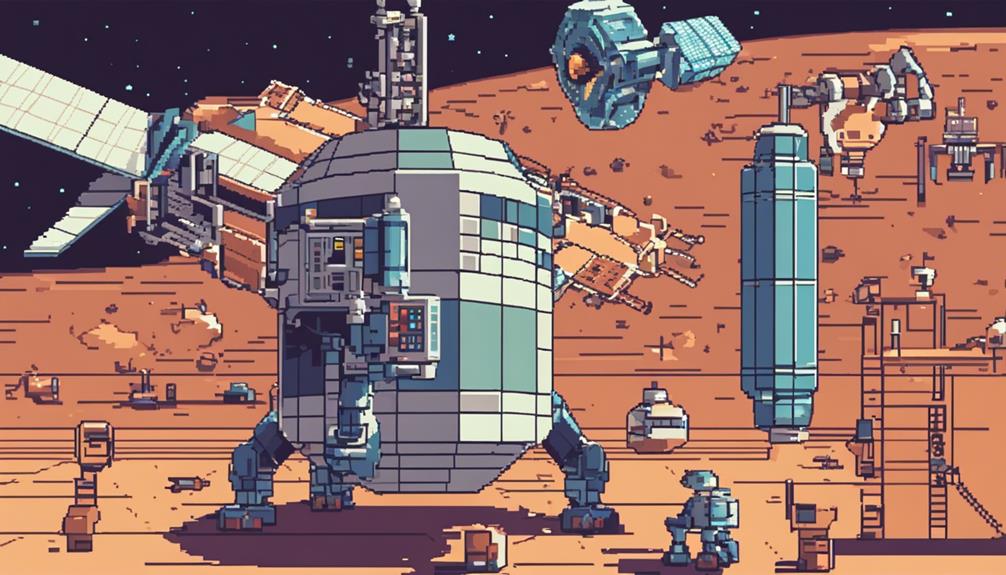

The evolution of satellite servicing can be traced back to the inaugural orbital repair mission carried out in 1984 by astronauts James van Hoften and George Nelson on the Solar Maximum Mission (SMM) satellite. This mission marked the beginning of a new era in space exploration, demonstrating the feasibility of on-orbit repairs and maintenance. Subsequent missions, such as the servicing of the Hubble Space Telescope through five missions between 1993 and 2009, further showcased the importance of satellite servicing in extending the lifespan and enhancing the capabilities of orbiting assets.

In 2007, the Orbital Express program was launched to develop autonomous capabilities for satellite servicing, aiming to enable safe and cost-effective maintenance in orbit. This initiative laid the groundwork for future advancements in on-orbit refueling and repair technologies. Concurrently, DARPA's Phoenix project, initiated in 2012, focused on recycling retired satellite parts and exploring innovative concepts for on-orbit servicing.

The growing interest in satellite servicing is exemplified by Northrop Grumman's contract with the U.S. government to study the feasibility of servicing national security satellites. This collaboration highlights the increasing importance of maintaining and upgrading critical assets in orbit to ensure the resilience and functionality of vital space infrastructure. As the in-space economy continues to expand, satellite servicing will play a crucial role in supporting the sustainability and longevity of satellite missions, as evidenced by discussions at events like the Space Symposium.

Advancements in Refueling Techniques

Recent advancements in refueling techniques have brought about new fueling technologies, improved fuel transfer methods, and enhanced refueling processes for satellites in orbit. These developments are crucial for optimizing satellite operations, ensuring efficient fuel replenishment, and increasing overall mission effectiveness. The evolution of refueling techniques is a key component in enhancing the sustainability and functionality of satellites in space.

New Fueling Technologies

Advancements in refueling techniques for on-orbit satellite servicing have revolutionized the industry, providing efficient solutions for extending satellite lifetime and enhancing operational capabilities.

- Orbit Fab's RAFTI enables easy satellite refueling in orbit with flight heritage.

- Accessing fuel in orbit helps defer capital costs, increase asset utilization, and extend satellite lifetime.

- Lockheed Martin invests in Gas Stations in Space™ technology for on-orbit refueling solutions.

These innovative technologies, like RAFTI and Gas Stations in Space™, are crucial for satellite operators looking to enhance mission flexibility and prolong the operational life of satellites in space. With the support of companies like Lockheed Martin, the adoption of on-orbit refueling is driving advancements in satellite servicing and setting new standards in the industry.

Improved Fuel Transfer

Improved fuel transfer techniques, such as Orbit Fab's Rapidly Attachable Fluid Transfer Interface (RAFTI), play a pivotal role in enhancing satellite refueling efficiency in orbit. RAFTI, with its flight heritage and integration within Orbit Fab's on-orbit refueling architecture, enables rapid and straightforward refueling of satellites. These advancements not only help defer capital costs but also increase asset utilization and extend the lifetime of satellites. By improving fuel transfer capabilities, spacecraft maneuverability and mission flexibility are enhanced. Satellite operators stand to benefit significantly from the extended mission life and increased operational efficiency brought about by these improved fuel transfer techniques, ultimately advancing the field of on-orbit refueling and satellite servicing.

Enhanced Refueling Processes

Building upon the foundation of improved fuel transfer techniques like RAFTI, the evolution of enhanced refueling processes in satellite servicing involves a systematic integration of cutting-edge advancements in refueling techniques. Companies like Orbit Fab and Northrop Grumman are at the forefront of developing in-orbit refueling technology, with Orbit Fab's Rapidly Attachable Fluid Transfer Interface (RAFTI) simplifying the satellite refueling process. Refueling satellites in orbit with RAFTI technology offers numerous benefits, including extending mission lifetimes, increasing operational flexibility, and reducing costs associated with launching new satellites. By utilizing advanced refueling techniques, satellite operators can optimize asset utilization and enhance overall mission efficiency.

- Extend mission lifetimes

- Increase operational flexibility

- Reduce costs

Key Technologies for On-Orbit Operations

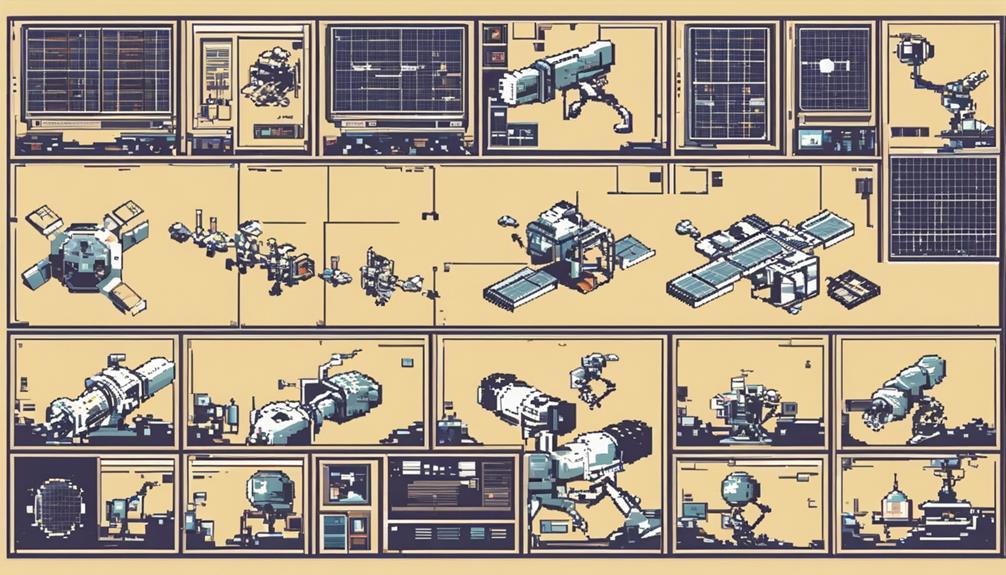

In the realm of on-orbit satellite operations, key technologies play a critical role in enabling efficient and reliable servicing and refueling capabilities. One notable advancement in this field is the development of the Attachable Fluid Transfer Interface (AFTI) by Orbit Fab. AFTI is pivotal for on-orbit satellite servicing, allowing for the transfer of propellants between spacecraft, enabling the extension of mission durations and enhancing operational flexibility.

Additionally, the concept of the Mission Augmentation Port (MAP) has gained significant attention in the realm of in-space servicing. The MAP serves as a standardized interface that facilitates the integration of various servicing technologies onto satellites, supporting a range of mission augmentation activities. This innovation has been particularly lauded by Space Operations entities and the Space Force for its potential to revolutionize on-orbit servicing capabilities.

Furthermore, the integration of advanced refueling systems like those demonstrated by Lockheed Martin's LINUSS system showcases the dedication to enhancing on-orbit operations. LINUSS, with its ASPIN docking adapter, not only enables mission enhancements but also paves the way for potential on-orbit refueling interfaces. This approach highlights a concerted effort towards mission resiliency and on-orbit servicing advancements, ultimately shaping the future landscape of satellite operations.

Current and Future Satellite Missions

Current and future satellite missions encompass a diverse range of objectives and technologies, from servicing aging satellites to deploying innovative mission augmentation systems. These missions showcase the evolution of on-orbit operations and the increasing reliance on advanced servicing capabilities. Understanding the mission types and the impact of technological advancements is crucial for the continued development and success of satellite servicing and refueling endeavors.

Mission Types Overview

As the landscape of satellite missions continues to evolve, a comprehensive overview of current and future mission types is essential for understanding the advancements in on-orbit satellite servicing and refueling. Some notable missions and initiatives include:

- Orbit Fab: Pioneering the development of in-space refueling systems for satellites to extend mission durations.

- DARPA's Rapidly Attachable Fluid Transfer: Enabling efficient servicing of satellites in geostationary orbit.

- Lockheed-Martin's Mission Augmentation Port (MAP) interface: Facilitating standardized interfaces for on-orbit satellite servicing and mission augmentation.

Technological Advancements Impact

Satellite missions are increasingly benefiting from pivotal technological advancements in on-orbit servicing, significantly impacting current and future space operations. Integration of refueling systems, such as those developed by Orbit Fab, allows for extending missions and servicing satellites in orbit efficiently. The incorporation of Mission Augmentation Ports on satellites enables in-space upgrades and maintenance, contributing to the sustainability and flexibility of space missions. Robotic servicing plays a crucial role in the success of on-orbit servicing, ensuring precision and safety in handling tasks. Refueling ports are being designed to facilitate in-space refueling processes, supporting the growing space economy by enhancing satellite capabilities and longevity. Continued innovation in on-orbit servicing technologies is essential for advancing the field and meeting the demands of future satellite missions.

Importance of Standardized Interfaces

Efficient and seamless connections between refuelers and satellites are enabled through the implementation of standardized interfaces in satellite servicing. These interfaces play a vital role in ensuring plug-and-play capabilities, allowing for the easy integration of refueling systems. By establishing hardware interoperability standards, compatibility and ease of use for in-orbit servicing are achieved. Here are some key points highlighting the importance of standardized interfaces:

- Mission Augmentation Port (MAP) Interface: The use of standardized interfaces like the Mission Augmentation Port (MAP) interface ensures that refueling systems can be quickly and securely attached to satellites, streamlining the refueling process.

- Space Enterprise Consortium: The Space Enterprise Consortium has been actively involved in developing interoperable standards such as the Tetra-5 experiment. These efforts promote early prototyping and the creation of plug-and-play solutions for satellite servicing.

- Efficient Refueling Operations: Standardized interfaces facilitate quick and reliable refueling operations in space. With predefined connection points and communication protocols, refuelers can easily interact with various satellites, enhancing overall mission efficiency and success.

Challenges and Solutions in Space Logistics

Navigating the intricate realm of space logistics presents a myriad of challenges that necessitate innovative solutions for ensuring the seamless refueling of satellites. One significant challenge lies in developing safe and efficient refueling mechanisms for satellites in orbit. To address this, integrating reliable robotic servicing systems is crucial to ensure compatibility with existing satellite architectures. Companies like Orbit Fab are pioneering the development of in-space refueling systems to service satellites and extend their mission life.

The Defense Advanced Research Projects Agency (DARPA) has been at the forefront of developing technologies such as the In-space Upgrade Satellite System and the Mission Augmentation Port (MAP) interface. These advancements aim to facilitate the docking and refueling processes in space. Moreover, the Space Systems Command is working on standardizing docking adapters to streamline the servicing procedures further.

Testing and validating refueling processes in space are essential steps towards successful on-orbit servicing implementation. Early planning, collaboration, and industry partnerships are crucial to advancing technology development in space logistics. Addressing regulatory and safety considerations is vital to ensure the effective and safe implementation of in-orbit servicing solutions, especially as the industry moves towards utilizing commercial services for satellite refueling.

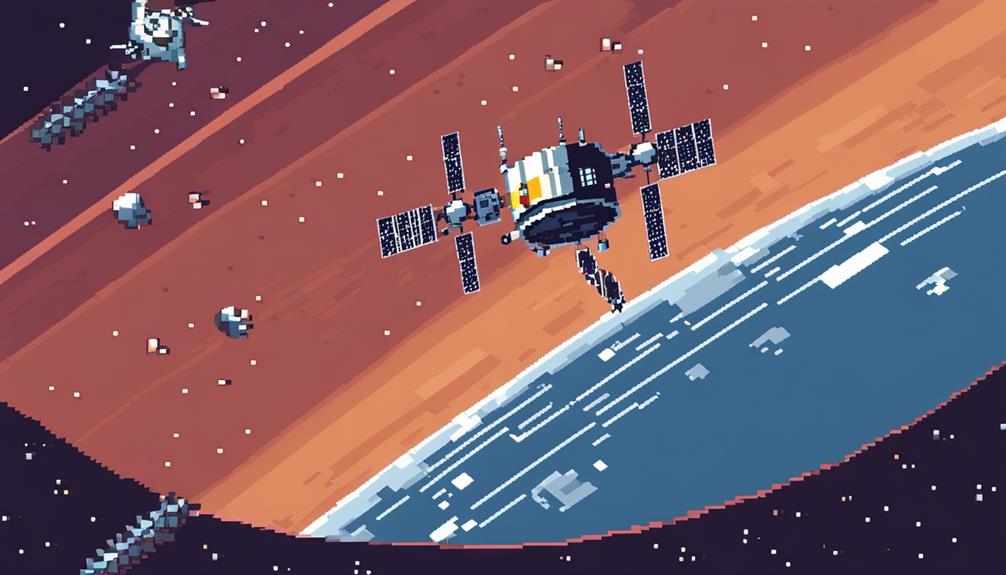

Potential Impact on Space Exploration

The integration of on-orbit satellite servicing and refueling technologies holds significant promise for revolutionizing space exploration capabilities. This advancement enables a wide range of benefits and opportunities for the space industry:

- Extended Mission Life: On-orbit servicing and refueling can extend the operational lifespan of satellites by replenishing fuel supplies, allowing for prolonged missions and enhanced data collection.

- Enhanced National Security: By enabling the refueling of satellites in geostationary orbit, this technology enhances national security applications by ensuring continuous and uninterrupted satellite operations crucial for surveillance and communication purposes.

- Facilitating In-Space Economy: In-orbit satellite servicing supports the development of an in-space economy by offering sustainable solutions for satellite maintenance and resource utilization, paving the way for future space exploration endeavors.

These innovations are made possible through advanced technologies like the Mission Augmentation Port (MAP) interface developed by Orbit Fab and initiatives by organizations like the Defense Advanced Research Projects Agency (DARPA) to enhance the capabilities of on-orbit servicing systems. The ability to service and refuel satellites in resident space not only increases operational efficiency but also opens up new horizons for exploration beyond Earth's orbit.

Frequently Asked Questions

Can a Satellite Be Refueled?

Yes, a satellite can be refueled, a critical aspect for space sustainability and extending mission lifespan. This process involves intricacies in fuel storage, orbital mechanics, and satellite maintenance. The practice enhances cost efficiency, reduces environmental impact, and enables more ambitious space exploration missions. However, innovating in on-orbit refueling poses challenges that necessitate advancements in future technology to ensure successful and sustainable operations in space.

Does a Satellite Require Fuel Once It Is in Orbit?

Satellites require fuel once in orbit for various crucial functions such as maintaining orbital maneuvers, attitude control, and collision avoidance. Fuel efficiency, propellant storage, and thruster maintenance play key roles in ensuring operational longevity. Efficient fuel consumption not only extends satellite life but also reduces costs. Incorporating advancements like solar panels and optimizing fuel usage can lead to significant efficiency gains and overall cost savings in satellite operations.

What Is on Orbit Refueling?

Fuel transfer in space, known as on-orbit refueling, is a critical process for space sustainability. It involves replenishing a satellite's propellant reserves to enable orbital maneuvers, extend mission durations, and reduce space debris by enhancing satellite maintenance. Refueling technology facilitates autonomous rendezvous for efficient fuel transfer, supporting mission extension and maximizing fuel efficiency in space operations. This process showcases advancements in space technology for long-term satellite functionality.

What Is in Orbit Servicing?

In-orbit servicing encompasses a suite of operations conducted in space to enhance satellite functionality, extend operational life, and mitigate space debris. This critical practice, at the intersection of space sustainability and technological advancement, enables orbital maintenance, supports space exploration initiatives, and fosters industry collaboration. By maximizing satellite longevity, ensuring mission flexibility, and exploring innovative opportunities, in-orbit servicing not only bolsters cost efficiency but also minimizes environmental impact through tailored servicing solutions.