In the realm of space exploration, the focus on sustainable satellite design and manufacturing has emerged as a critical consideration for the future of space endeavors. The intricate balance between technological advancements and environmental consciousness in spacecraft development poses a challenge that necessitates innovative solutions. By exploring the intersection of sustainability and satellite engineering, a profound impact can be made on space missions' longevity and ecological footprint. The evolution of sustainable practices in satellite production not only ensures operational efficiency but also sets a precedent for a more conscientious approach to space exploration.

Key Takeaways

- Sustainable satellite design reduces environmental impact and promotes longevity.

- Innovative manufacturing processes focus on efficiency and waste reduction.

- Recycling and circular economy principles enhance sustainability in satellite production.

- Future trends prioritize electric propulsion, modularity, and advanced materials for sustainable satellites.

Environmental Impact of Satellite Manufacturing

Satellite manufacturing processes significantly contribute to greenhouse gas emissions, resource consumption, and waste generation, thereby posing substantial environmental challenges. The environmental impact of satellite manufacturing is primarily due to the chemicals, materials, and energy-intensive processes involved in their production. To address this impact, sustainable material choices, energy-efficient processes, and waste reduction strategies are essential.

In satellite manufacturing, the selection of materials plays a crucial role in determining the environmental footprint. Opting for eco-friendly and recyclable materials can help reduce the overall impact on the environment. Additionally, implementing energy-efficient processes during satellite assembly and testing phases can lower energy consumption and, consequently, greenhouse gas emissions. These practices not only mitigate environmental harm but also contribute to cost savings in the long run.

Moreover, waste reduction strategies are imperative in satellite manufacturing to minimize the amount of waste generated during production. Proper waste management techniques, such as recycling and reusing materials wherever possible, can significantly reduce the environmental burden of satellite manufacturing processes. By embracing green manufacturing practices and prioritizing sustainability in material choices and processes, the satellite industry can work towards reducing its environmental impact and moving towards a more sustainable future.

Sustainable Design Practices in Satellite Industry

With a focus on reducing environmental impact and promoting sustainability, the satellite industry implements sustainable design practices aimed at minimizing space debris and energy consumption. Satellite manufacturers prioritize the use of sustainable technologies that enable efficient end-of-life disposal and recycling, contributing to responsible space practices. By designing satellites for longevity and reliability, the industry aims to reduce the frequency of replacements, ultimately enhancing sustainability efforts.

Incorporating energy-efficient systems and solar panels in satellite design plays a crucial role in minimizing the consumption of non-renewable resources during operation. These measures not only decrease the environmental footprint of satellite missions but also promote the efficient use of energy throughout the satellite's lifecycle.

Furthermore, collaborative efforts within the satellite industry are essential for establishing standards and best practices for sustainable satellite design and manufacturing processes. By working together, industry stakeholders can drive innovation in sustainable practices, ensuring that satellites are developed and operated in a more environmentally friendly manner. This collective approach is key to advancing the responsible and sustainable growth of the satellite industry while mitigating potential negative impacts on the space environment.

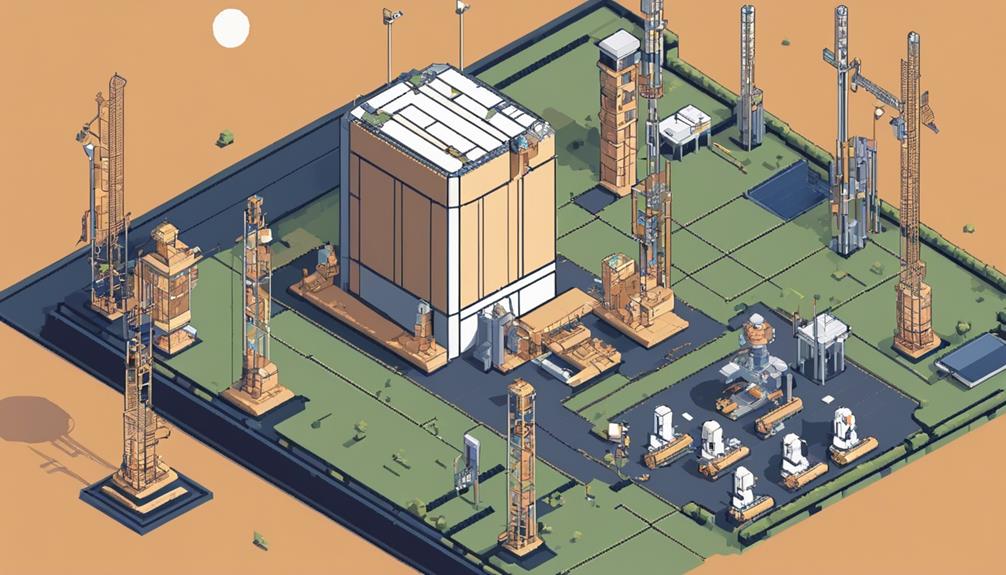

Innovations in Satellite Manufacturing Processes

Incorporating cutting-edge techniques and materials, the latest advancements in satellite manufacturing processes are revolutionizing the industry's approach to satellite construction. Additive manufacturing plays a pivotal role in expediting production timelines and reducing costs. Modular design and in-space assembly techniques offer increased flexibility and scalability in satellite construction, allowing for easier upgrades and repairs. The utilization of composite materials and lightweight components contributes to enhancing satellite performance while simultaneously decreasing overall mass, ultimately leading to improved efficiency.

| Innovation | Description | Benefits |

|---|---|---|

| Additive Manufacturing | Utilizes 3D printing technology for rapid and cost-effective production of satellite components. | Faster production, cost reduction |

| Modular Design | Allows for the construction of satellites in smaller, interchangeable modules for enhanced flexibility. | Scalability, easier upgrades and repairs |

| Composite Materials | Integration of lightweight materials like carbon fiber to improve satellite performance. | Enhanced efficiency, reduced overall mass |

| Smart Manufacturing Technologies | Incorporates AI and robotics to optimize manufacturing processes, ensuring quality control and efficiency. | Enhanced efficiency, quality control |

Sustainable manufacturing practices are at the core of these innovations, focusing on reducing waste, energy consumption, and environmental impact in satellite production. The integration of smart manufacturing technologies further enhances efficiency and quality control throughout the manufacturing process. As the industry continues to evolve, these advancements pave the way for a more sustainable and technologically advanced satellite manufacturing landscape.

Importance of Recycling in Satellite Design

Recycling plays a crucial role in enhancing the sustainability of satellite design practices by repurposing materials and minimizing waste. In satellite design, recycling offers a means to reduce waste generation and promote sustainability by reusing components to create new parts. By incorporating recycling processes, the satellite industry can effectively lower its environmental impact and carbon footprint. Repurposing materials through recycling not only conserves resources but also helps in the efficient use of energy during satellite manufacturing.

The adoption of recycling practices in satellite design aligns with the principles of a circular economy, where materials are reused and recycled in a closed-loop system. This approach contributes to the conservation of raw materials and reduces the reliance on extracting new resources for satellite production. Moreover, recycling in satellite design supports the concept of a circular economy in space technology, where materials are continuously repurposed to create new satellite components, further promoting sustainability within the industry.

Future Trends in Sustainable Satellite Technology

The evolution of sustainable satellite technology is paving the way for innovative approaches that prioritize efficiency, longevity, and reduced environmental impact in space exploration. Future trends in sustainable satellite technology are shaping the way for more advanced and environmentally friendly space technologies. Here are some key trends:

- Electric Propulsion Systems: Sustainable satellites are increasingly utilizing electric propulsion systems to reduce reliance on traditional fuel sources. This shift not only decreases the environmental impact of satellite operations but also enhances their overall efficiency.

- Modular Components: Future satellites are being designed with modular and upgradable components. This approach extends operational lifetimes, reduces overall waste, and allows for easier maintenance and upgrades in space.

- Materials Science Advancements: Advancements in materials science are enabling the development of lightweight, durable satellite structures. These new materials enhance sustainability in space by reducing the weight of satellites and improving their resistance to harsh space conditions.

- Integration of AI and Autonomous Systems: The integration of AI and autonomous systems in satellite design and operations is becoming more prevalent. These technologies enhance operational efficiency, reduce the need for human intervention, and contribute to sustainable practices by optimizing satellite functions.

These trends, coupled with collaborative efforts in the space industry to standardize sustainable practices, are driving the future of sustainable satellite technology towards a more efficient, durable, and environmentally conscious approach to space exploration.

Frequently Asked Questions

How Are Satellites Manufactured?

Satellites are meticulously manufactured using advanced assembly techniques and precise material selection. The manufacturing process involves integrating components like solar panels and antennas with strict quality control measures. Rigorous testing procedures simulate space conditions to ensure functionality and performance. The environmental impact is minimized through clean room facilities and efficient production methods. Collaboration between aerospace companies and suppliers ensures reliability and quality throughout the satellite manufacturing process.

Who Manufactures US Satellites?

Major manufacturers of US satellites include Boeing, Lockheed Martin, Northrop Grumman, and Space Systems Loral. These companies secure government contracts, partner internationally, and compete fiercely in the industry. They leverage technological advancements to produce a wide range of satellite types for various applications. Private companies like SpaceX also play a significant role in satellite manufacturing, further intensifying competition and driving innovation in the market.

What Are Some of the Obstacles to Manufacturing in Space?

Manufacturing in space faces numerous obstacles such as space debris posing collision risks, resource scarcity demanding efficient utilization, and regulatory challenges requiring compliance. Technology limitations restrict manufacturing capabilities, while cost constraints impact feasibility. For instance, developing a sustainable manufacturing process in microgravity environments demands innovative solutions to ensure safety, quality, and environmental impact mitigation. Addressing these challenges is crucial for advancing in-space manufacturing and sustainable satellite design.

What Company Builds Rockets for Nasa?

Northrop Grumman is the company responsible for building rockets for NASA. In addition to manufacturing rockets, Northrop Grumman also designs and launches spacecraft, such as the Cygnus spacecraft, to deliver supplies and experiments to the International Space Station. Their partnership with NASA ensures reliable and efficient access to space for various scientific research and technology development missions. Other notable companies involved in space exploration include SpaceX, Blue Origin, United Launch Alliance, Boeing, and Lockheed Martin.